WHAT IS THREE PHASE INDUCTION MOTOR?

OVERVIEW

1.1 RATIONAL

1.2 INTRODUCTION

1.3 COMPONENTS AND CONSTRUCTION

1.4 WORKING PRINCIPL

1.5 CLASSIFICATION

1.6 ADVANTAGES AND DISADVANTAGES

1.7 APPLICATIONS

1.1 RATIONALE

🔶Induction motor are widely used in various industries as driven motor for variety of machines.

🔶Due to its rugged construction, smoother and efficient operation , it has replaced dc motor in variety of applications.

🔶By reason of important role played by synchronous machines(alternators and motor) in the electrical generation system, the electrical technologist also need to be well versed in the construction and working of these machine.

1.2 INTRODUCTION

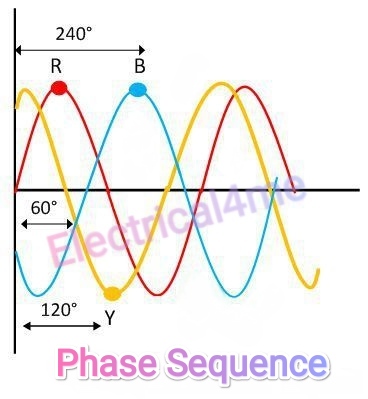

🔶The induction motor are basically ac motors i,e they need an alternating voltage as the source of energy for their operation.

🔶They can operate on either single phase or three phase ac supply. In almost 85%three phase induction motor are preferred.

1.3 COMPONENTS AND CONSTRUCTION

1.3.1 COMPONENTS

1.3.2 CONSTRUCTION

🔶Three phase induction motor is the most widely used electrical motor.

🔶Mechanical power used by the industries is provided by three phase induction motor.

🔶The power is transfer from stator to rotar winding through induction.

🔶Parts:

1.stator. 2.rotar

1.STATOR

🔶 Stationary part of induction motor.

🔶 A stator winding is placed in the stator of induction motor and the three phase supply is given to it.

🔶 It made from high grade alloy steel

2. ROTOR

🔶 Rotating part of induction motor.

🔶 Is connected to the mechanical load through the shaft.

🔶 Classification of Rotor:

a) Squirrel cage rotor this type of motor is known as asynchronous.

b) Slip ring rotor this type of motor is known as synchronous.

a) ASYNCHRONOUS MOTOR.

🔶 Induction motor works on the principle of induction i.e , when the power supply is given to the stator, it produces rotating magnetic field which gets induced in the rotor of induction motor causing rotor to rotate. As they run at asynchronous speed they are called asynchronous motor.

b) SYNCHRONOUS MOTOR.

🔶 This magnetic field will rotate at a certain speed (which depends on the frequency of the supply and no of poles), also called synchronous speed.

Therefore the rotor rotates at the same speed that of the rotating magnetic field. It is due to the reason the motor is called as synchronous motor.

1.4 WORKING PRINCIPL

🔶 The cause of production of rotor current is the relative velocity between rotating stator flux and the rotor, the rotor will try to catch up with the stator RMF .

Thus the rotor rotates in the same direction as that of stator flux to minimize the relative velocity.

🔶 However, the rotor never succeeds in catching up the synchronous speed .

🔴 This is the basic working principle of induction motor .

1.5 CLASSIFICATION

🔶 SYNCHRONOUS MOTOR

🔶ASYNCHRONOUS MOTOR.

1.5.1 SYNCHRONOUS MOTOR

🔶 This magnetic field will rotate at a certain speed (which depends on the frequency of the supply and no of poles), also called synchronous speed.

Therefore the rotor rotates at the same speed that of the rotating magnetic field. It is due to the reason the motor is called as synchronous motor.

1.5.2 ASYNCHRONOUS MOTOR

🔶 Induction motor works on the principle of induction i.e , when the power supply is given to the stator, it produces rotating magnetic field which gets induced in the rotor of induction motor causing rotor to rotate. As they run at asynchronous speed they are called asynchronous motor.

1.6 ADVANTAGES AND DISADVANTAGES

🔶 ADVANTAGES

1.low cost .

2. low maintenance cost.

3.speed variation.

4. easy of operation.

🔶DISADVANTAGES

1.poor starting torque.

2.always operate under lagging factor.

3. speed control of induction motor are difficult.

1.7 APPLICATIONS

🔶 Lathes

🔶 Drilling machines

🔶 Agricultural and industrial pumps

🔶 Industrial drives.

🔶 Crushers.

🔶Oil extracting mills.

🔶Textile and etc.

1.8 Compressors and Pumps

🔶Three-phase induction motors are commonly used in compressors and pumps, where they provide a reliable and efficient source of power.

1.9 Fans and Blowers

🔶Three-phase induction motors are also used in fans and blowers, where they provide a low-cost solution for air circulation.

1.10 Conveyors and Hoists

🔶Three-phase induction motors are often used in conveyors and hoists, where they provide a powerful and reliable source of mechanical energy.

1.11 Machine Tools

🔶Three-phase induction motors are also used in machine tools, where they provide a high degree of precision and accuracy.

1.12 Conclusion

🔶In conclusion, the three-phase induction motor is a widely used type of electric motor that provides a reliable and efficient source of mechanical energy. It consists of two main parts, the stator, and the rotor, and there are two main types, the squirrel cage motor, and the wound rotor motor. They are used in a wide range of industrial and commercial applications, including compressors and pumps, fans and blowers, conveyors and hoists, and machine tools.

1.13 FAQs

🔶What is the difference between a three-phase induction motor and a single-phase induction motor?

A: A three-phase induction motor requires a three-phase power supply, while a single-phase induction motor requires a single-phase power supply.

🔶What is the efficiency of a three-phase induction motor?

A: The efficiency of a three-phase induction motor varies depending on the specific motor, but it is typically between 70.

.png)